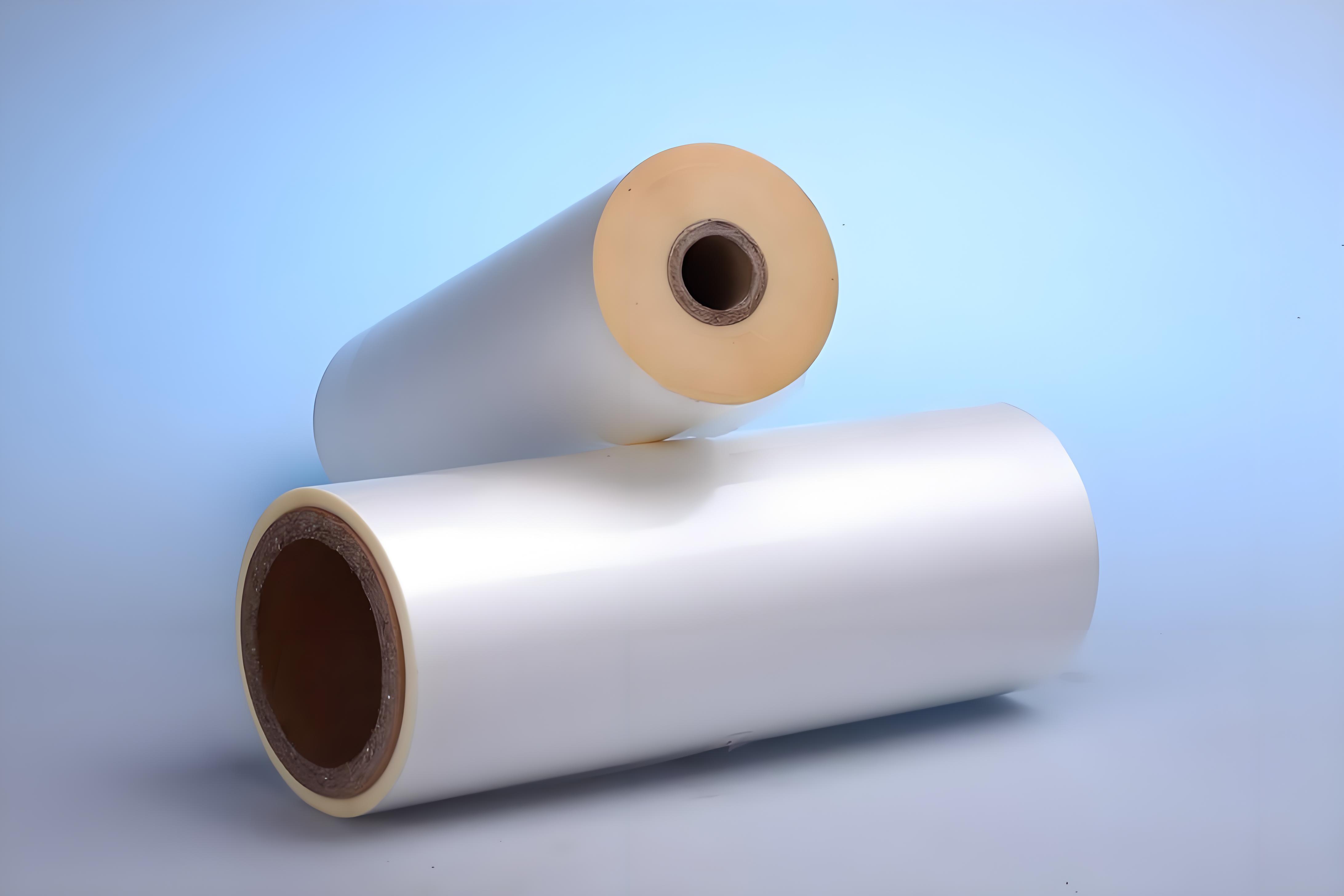

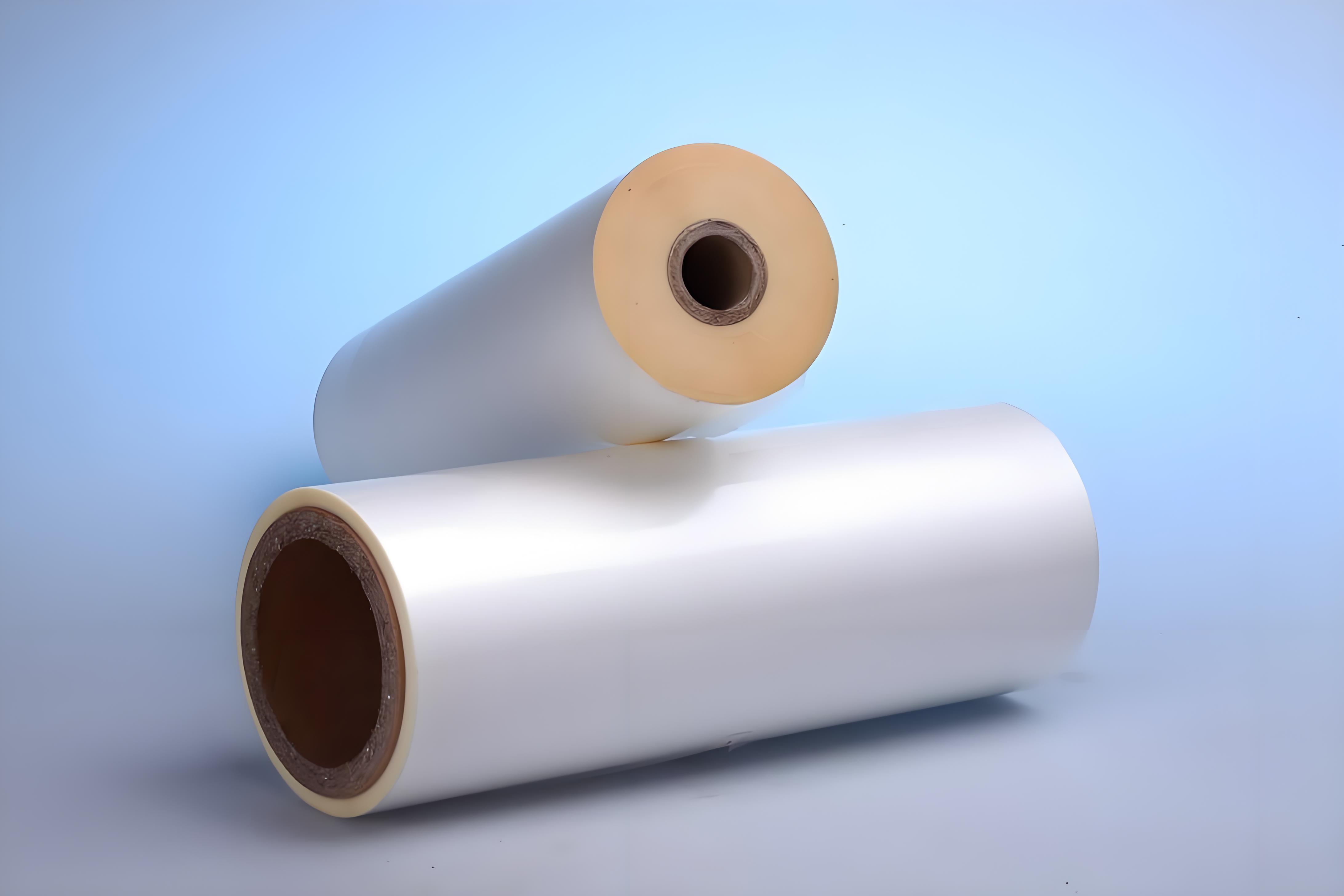

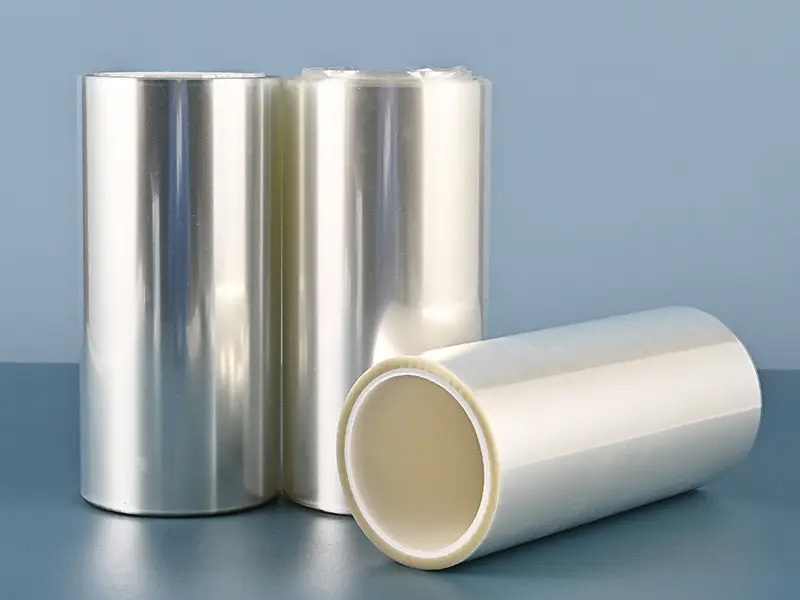

Product Introduction - BOPP Pre-coated Film

06

/

06

2024

Market Prospects Analysis of Pre-coated Films

05

/

15

2024

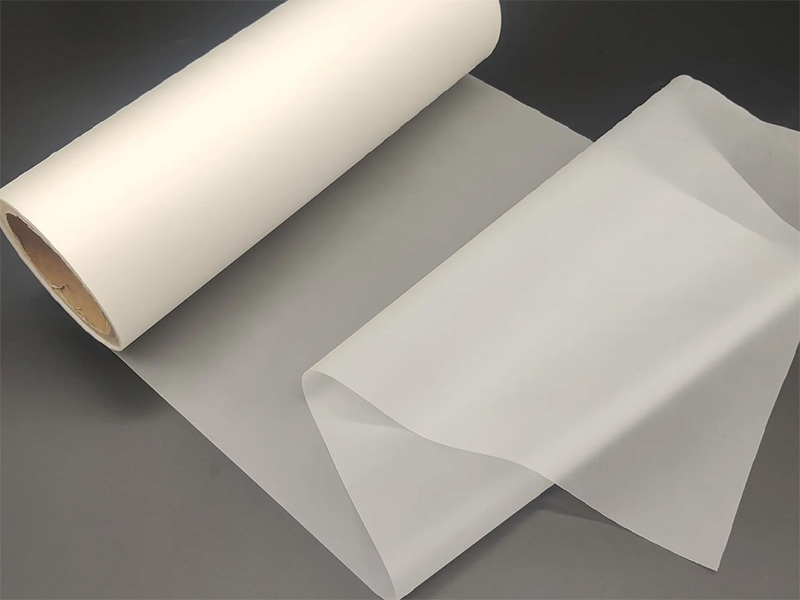

What are the types of pre film

01

/

04

2024

How to choose the precoated film

12

/

20

2023

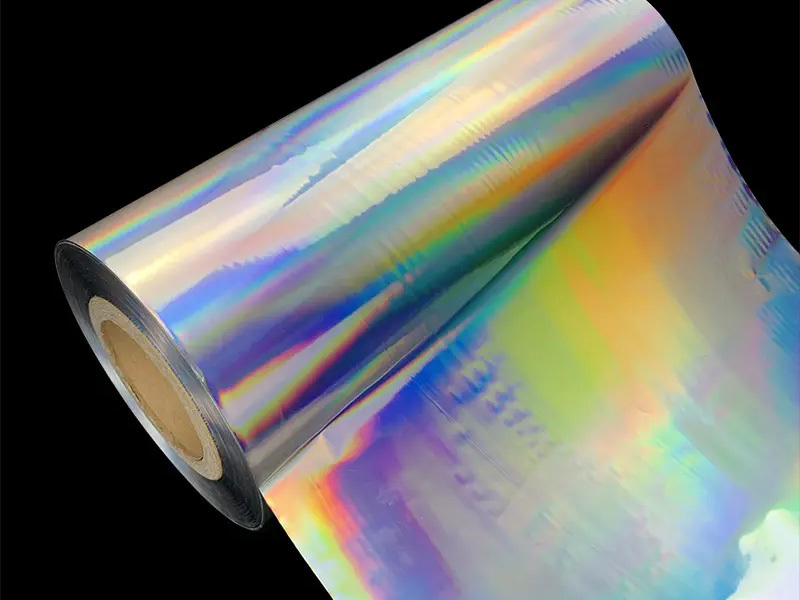

What factors should be paid attention to when buying laser thickened lettering film

10

/

18

2023

08

/

23

2023

The difference between BOPP precoated film and PET precoated film

07

/

27

2023

Pre-coating film relative to the more prominent advantages

06

/

15

2023

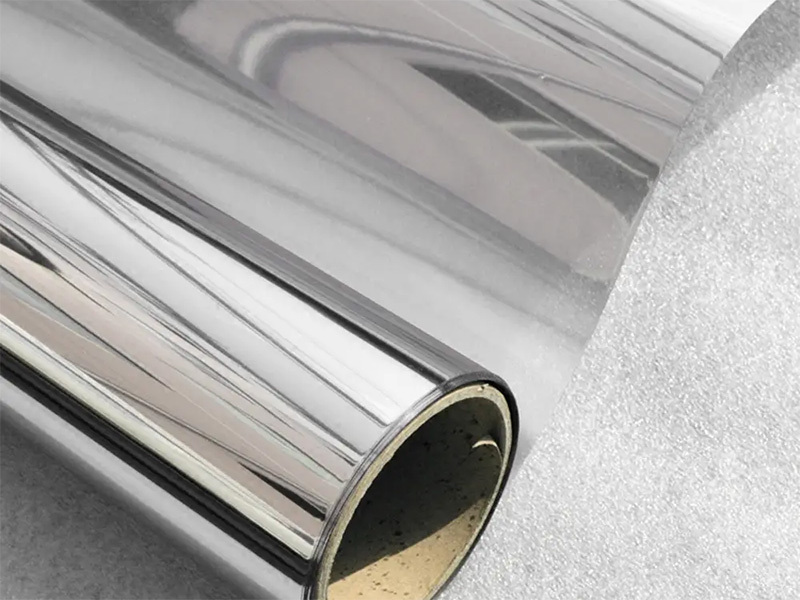

The working principle of reflective film

06

/

08

2023

Introduction of several advantages of pre-coated film pre-coated film

05

/

22

2023